Monitoring Ground Conditions

Thurber's instrumentation engineers and technicians are vital to the success of any investigation and construction project. Using specialized equipment, our instrumentation team works with our geotechnical, materials, and environmental engineers to measure and monitor a variety of soil and groundwater conditions. This includes soil deformation on slopes, anchor loads, groundwater levels, water quality, temperatures, and strain in structures. Together, we help understand site conditions accurately to mitigate risks on, above, or below the ground during design, construction, and post-construction. We provide monitoring services for existing structures, oil and gas observation wells, sensitive environments that impact groundwater, and retaining walls.

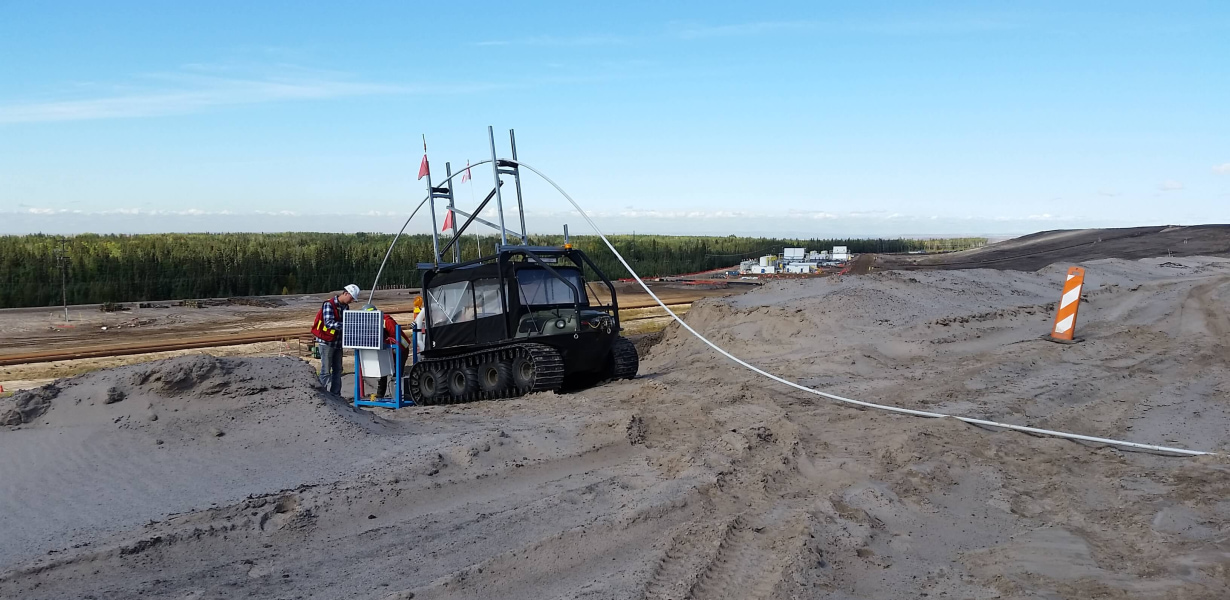

We use a variety of instruments and purpose-built systems to meet the specific needs of your site, whether it be in a busy urban environment or off-grid at a remote site. Our automated systems can also be equipped with telemetry that allows us to access data remotely, thereby reducing the number of site visits.

Here's how instrumentation can help your project:

- Detecting and measuring earth movement on sensitive slopes

- Measuring settlement of embankments or structures during and after construction

- Monitoring retaining walls to protect workers and the public during deep excavations

- Monitoring fluid pressure and temperatures below the ground surface on projects with sensitive conditions

- Automated remote data collection to reduce personnel visiting potentially high-risk safety environments

- Adjustable data collection frequencies to make more informed decisions about site conditions or mitigation plans

Thurber assists our clients during all project stages. We provide tailored instrumentation solutions to meet your project's specific needs.

- Field pumping systems for contaminated groundwater

- Monitoring flow rates, storage tank volumes, groundwater characterization sensors

- Vapor extraction pumps (pictured above)

- Weather stations

- Developing instrumentation and monitoring plans to suit the observation approach or trigger and alarm protocols (TARPs)

- Earth structure and water and tailings dam monitoring using Shape Acceleration Arrays (SAA) , Vibrating Wire (VW) Piezometers, and/or Total Pressure Cells

- Retaining wall performance monitoring using strain gauges, SAA, anchor load cells, and VW

- Piezometers

- Steam Assisted Gravity Drainage (SAGD) reservoir monitoring using VW Piezometers and suspended thermocouples

- SPT hammer energy measurement

- Frost penetration using thermistor strings

- Pavement structure temperature and settlement monitoring using extensometers

- Slope stability monitoring using in-place inclinometers or SAA

- Foundation settlement during and post-embankment fill construction using settlement plates, liquid settlement cells, and/or horizontal SAA instruments

- Static pile load testing using load cells, displacement sensors, and/or embedded strain gauges

- Deep foundation testing

- High-strain dynamic pile load testing (PDA testing)

- Low-strain pile integrity testing (PIT testing or Pulse Echo)

- Thermal integrity profiling (TIP testing)

- Crosshole sonic logging (CSL testing)

Vibration during construction can cause cracks in neighbouring structures and generally disturb inhabitants and/or facility users. Using vibration monitoring on a construction project is a clear win for the contractor: it provides peace of mind and cost savings by reducing the risk of damage to nearby infrastructure. The data provided by vibration monitoring also supports contractors in the event of litigation: they can prove that they did not exceed vibration tolerances as defined by project requirements. Thurber has the experience and equipment to provide vibration monitoring for clients on projects of all sizes.

.jpg?resize=410x0)

.jpg?resize=410x0)