Long Lasting Structures

When building or maintaining infrastructure, we all want the same thing: quality and safety. Infrastructure must withstand the elements (rain, freeze thaw, etc.), resist corrosion, and last for the prescribed service life. This is where construction materials engineers come in. The choice of coatings, the corrosivity of the soil, or the building materials used all impact a structure's lifespan. We test, design, and optimize construction materials to achieve or increase a structure’s life.

Our quality assurance services during design and construction give owners peace of mind by ensuring the materials conform to building code and design specifications. Contractors benefit from our quality control services that help detect defects early, thereby reducing the need for costly repairs and rework.

Our construction materials engineers understand how to achieve or increase the structural life of new and existing infrastructure. We work with designers and owners to design, develop, and optimize the materials chosen in advance of construction. By involving us in the design of your project, we help save time and money, increase quality, and ensure that problems are mitigated early.

During construction, we provide in-place condition evaluation/construction monitoring services to determine if construction procedures and materials conform to project specifications, design

assumptions, and good construction practices. Our monitoring and testing services include:

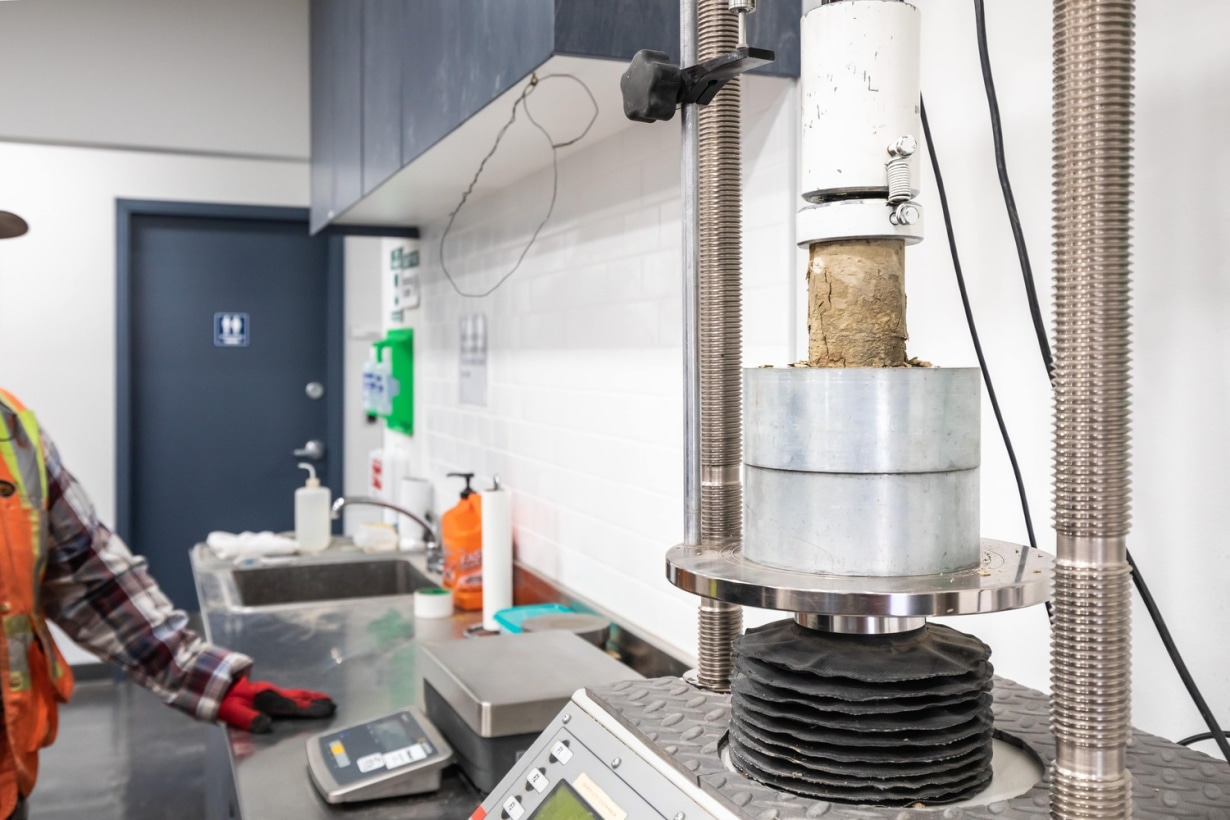

- Construction materials testing for soil, aggregates, asphalt, concrete, grout, mortar, bricks, and blocks

- Pile construction monitoring

- Soil, concrete, and asphalt placement monitoring

- Materials quality assurance and quality control programs

- Quality assurance and quality control testing

- Aggregate crusher product

- Support fluid testing for deep foundations

- Instrumentation of rock, earthworks, and permafrost

- Pile load testing

- Blasting and construction vibration monitoring

- Supervision of drilling, coring, and in-situ testing

- Site and laboratory testing for soil liners

- Technical specification preparation for soil, concrete, and asphalt

- Verification of compliance to specifications and QA/QC requirements

- Mass concrete thermal modelling

- Soil corrosivity testing

Thurber provides non-destructive testing (NDT) and non-destructive evaluations (NDE) to support you in:

- assessing structural integrity

- planning for repair, rehabilitation, and maintenance

- assessing durability

- optimizing performance

- conducting life cycle analysis

- enhancing safety

Non-destructive testing/evaluation methods can help determine element thickness and identify cracks (depth and length), voids, honeycombing, discontinuities, poor quality concrete, estimate compressive strength, and corrosion potential of hardened concrete.

We provide non-destructive testing for:

- Aging concrete structures (bridges, buildings, parkades)

- Forensic investigations related to concrete, soils, and asphaltic materials

- Water resource infrastructure (dams and reservoirs)

- Pre-cast concrete elements (reinforced concrete girders, wall panels, and pipes)

- Post-tensioned ducts to locate and identify grouting defects

- Concrete elements reinforced with steel fibres

- New concrete builds where quality issues arise during construction

- Culturally sensitive building where destructive test methods may not be ideal

- Steel bridges and other structural steel elements

Ground Penetrating Radar (GPR)/Rebar Survey

GPR uses electromagnetic waves to:

- Estimate concrete/pavement thickness, locate steel reinforcement (rebar), and identify voids, conduits, and post-tension cables.

- Assist contractors in identifying rebar elevations prior to bridge deck milling operations.

- Assess road structures by helping estimate asphalt/concrete pavement and gravel base thickness.

Thurber has multiple GPR units: we scan small areas with handheld equipment, bridge decks using pushcarts, and long sections of roadway using tow behind GPR.

Ultrasonic Pulse Echo (UPE)

UPE scanning can be completed when only one side of a concrete element is accessible. It uses acoustic stress waves to:

- Estimate thickeness and detect flaws like voids, delamination, de-bonding, honeycombing, and cracking

- Detect closely spaced rebar that GPR might not be able to differentiate

- Locate rebar embedded in steel fiber reinforced concrete

UPE used with GPR makes for a powerful combination that can locate post-tensioned ducts and identify grouting defects.

Ultrasonic Pulse Velocity (UPV)

UPV uses transducers that transmit and receive timed pulses of ultrasonic energy which travel through concrete to identify uniformity and discontinuities. UPV requires access to both sides of a concrete member (columns, piers, walls, and grade beams are ideal elements).

UPV can be used to assess the quality of concrete over large areas to select sections for further testing.

Combining data from UPV and rebound hammer testing can help estimate the compressive strength of concrete.

Impact Echo (IE)

IE works by striking the surface of a concrete element with various weighted hammers, creating a wave impulse that propagates through the concrete and reflects once it hits boundaries or defects. IE is effective in determining the thickness of concrete elements when they can only be accessed by one side (tunnel linings, concrete tanks/pipes, and slabs). It can also be used to identify voids, honeycombing, debonding, delamination, and assess concrete quality.

As structures age, they require condition surveys to assess for structural and condition issues. We provide visual surveys and in-depth materials laboratory testing to determine a

structure's condition. We assess soil, timber, steel, and reinforced concrete to understand the exposure conditions acting on the structure. Our team assesses the material’s

strength, corrosion potential, chloride content, coatings, and steel thickness.

Our services include:

- Concrete compressive strength evaluation

- Concrete corrosion potential rate analysis

- Chloride content analysis

- Laser scanning for chloride/sulphate profiles

- Rebar cover surveys

- Concrete coatings assessment

- Structural steel coating evaluation

- Lead content coating analysis

- Structural steel thickness evaluation

- Assessment of steel corrosion in soil

- Geotechnical assessment of soil structures

- Timber fire damage assessment

- Timber rot extent determination

- Non-destructive testing on concrete: Ground Penetrating Radar, Ultrasonic Pulse Echo, Ultrasonic Pulse Velocity, and Impact Echo

- Delamination survey on concrete structures

- Copper Sulphate Electrode (CSE) surveys, chloride profiling, rebar cover surveys, and carbonation evaluation

- Bridge load testing to evaluate load-carrying capacity

- Air void testing of concrete

Whether you’re designing a new structure or rehabilitating an older one, the choice of coatings and liners can impact the structure’s longevity and environmental impact. Thurber

provides the following services:

- Coating and lining specification writing/review

- Coating and lining selection

- Service-life modelling

- Failure analysis

- Quality assurance/control

- Monitoring of environmental conditions

- Coating thickness evaluation

- Surface preparation evaluation

- Adhesion testing

- Lead content analysis and abatement planning

- Development of Environmental Management Plans

- Silica exposure control plans

- Steel corrosion assessment using ultrasonic methods

.jpg?1500x844)

Once a structure is assessed and tested, we can predict its remaining service life. Our services include:

- Test result interpretation to estimate in-situ compressive strength of concrete

- Time to depassivation of reinforcing steel based on state-of-the-art probabilistic methods

- Determination of corrosion state of concrete

- Feasibility assessment of the use of cathodic protection (impressed or galvanic) to extend service life

- Structural steel coating assessment

- Remaining service life estimate for coatings on structural steel

- Assessment of corrosion activity of buried steel structures

If our clients choose to extend the service life of a structure, we work with the structure’s owner and structural engineer to select an appropriate repair/maintenance approach. Our

services include:

- Design of repairs to infrastructure to extend service life

- Development or review of project specification to achieve extended service life

- Material selection and review of contractor qualifications for repair work

- Project monitoring to quality assurance/control

- Development of quality assurance/control programs and plans

- Lead abatement planning

Our laboratory capabilities range from routine construction materials tests to advanced testing for complex challenges. All laboratory and field testing meets the required ASTM, CSA, AASHTO,

or region/client-specific procedures. Serving clients across Canada, our speciality testing services include:

- Post-construction concrete evaluation and analysis

- Portland cement concrete and shotcrete technology

- Asphalt concrete technology

- Concrete mixture designs and reviews

- Pavement design and evaluation

- Admixture, silica fume, and fly ash evaluation

- Aggregate resource surveys

- Alkali-aggregate reactions

- Concrete bridge deck and parkade slab evaluation

- Rebar corrosion survey data evaluation

- Soil corrosivity and resistivity testing

- Chloride diffusion analysis

- Materials failure and insurance investigations

- Non-destructive testing and evaluation

- Research and development of materials and products

- Thermal modelling of concrete

- Concrete QA/QC

Thurber offers specialized pavement engineering and testing services for highways, airports, roadways, and parking lots. Our pavement engineers work with our construction materials engineers to focus on the design, construction, and maintenance of roads and pavement. Our team has an in-depth understanding of pavement materials, design methods, construction techniques, and pavement performance. Our team helps clients optimize their pavement designs to accommodate traffic loads, climate conditions, and soil conditions.

-8.jpg?resize=410x0)

-4.jpg?resize=410x0)